Brake Fluid Supply Bottle

I do all the maintenance on my bikes by myself, so I need to be a little creative when it comes to replacing brake and clutch fluid, as this is usually a two-person job.

For the caliper end of things, I use Stahlbus bleeder valves. They're far superior to SpeedBleeders, and worth the price. (see discussion below)

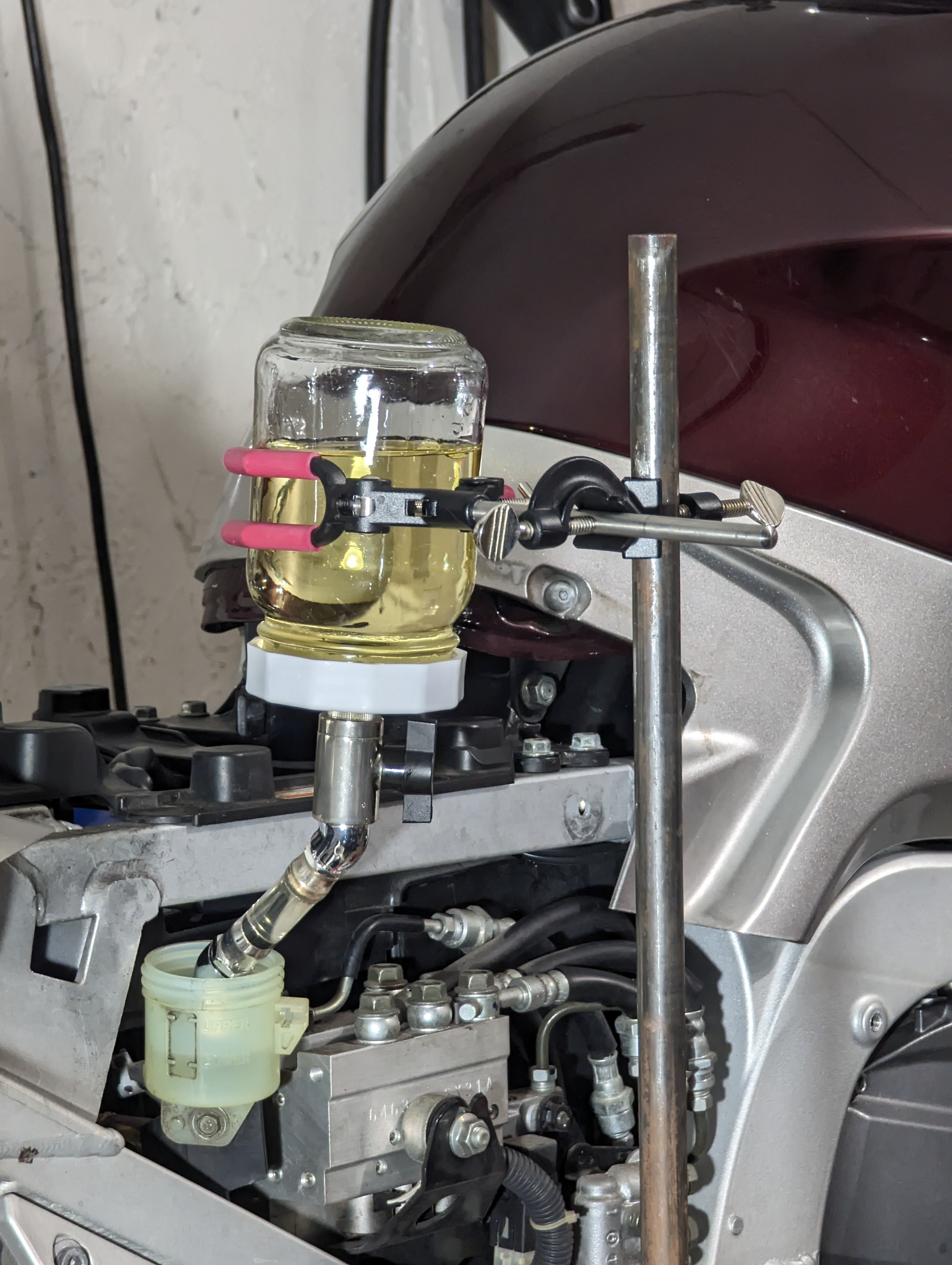

For the master cylinder end, I created a cheap brake fluid supply bottle out of a pint Mason canning jar and $30 in computer water-cooling parts. It has a valve to open and close it.

To hold it in place, I use a small plate with a thumbscrew that screws into the same hole that holds on the master cylinder lid.

I've used pressure bleeders and other equipment, but this is the simplest and cleanest method I've used so far.

I've used commercial supply bottles, but they're all designed for cars and don't attach well to the master cylinder, and the valves are usually very poor quality. They end up leaking fluid everywhere, and make more of a mess and hassle than they save.

Close the valve, then flip the bottle over.

The thumbscrew simply threads into one of the master cylinder lid screw holes with the standard M4 thread used by all Japanese bikes - and the Italian and German ones I've run into as well.

Open the valve. As the fluid drops below the barb, air bubbles into the bottle, which releases fluid to raise the level back up to the bottom of the barb. It's the same principle as Harbor Freight or Mityvac bottles, but it actually works.

They're generic parts you should be able to find anywhere online.

|

Ball valve (10mm) G1/4" ($19) Prevents spilling when the bottle is inverted. |

|

G1/4" to 1/2" barb fitting ($3) Controls the level of fluid in the master cylinder reservoir. Get a "stubby" fitting to allow a higher level of fluid in the master cylinder. You need 1 for the front brakes, and 3 for the rear brakes. |

|

G1/4" to G1/4" bulkhead fitting ($5) Seals the bottle lid and provides a mount for everything else. |

|

Nozzle coupling adapter, G1/4" male-male ($3) Connects the ball valve to the other parts. 2 required |

|

Pass-through G1/4" ($7) Supports the mounting plate. |

|

45° adapter G1/4" male-female ($7) For the rear brake extension. |

|

45° adapter G1/4" female-female ($5) For the rear brake extension. |

Other required parts

|

Rear brakes are a challenge because the master cylinder reservoir is tucked into the bike, and some systems don't even have one.

You can get a 3-prong or 4-prong clamp for lab glassware, and a corresponding right angle clamp that holds it to a vertical rod.

I got a 3ft long 5/8" steel rod from Lowe's, which fits into a Manfrotto #171 Mini Clamp, that clamps to the edge of the Harbor Freight bike lift. That clamp is a bit expensive, but there are "tiki torch deck clamps" available that might work. I don't know how rigid they are.

Add the two 45° adapters, 3 barb fittings, and a 2" piece of clear hose, and you will have something with the required reach that's very adjustable and very stable.

If you don't have a bike lift, then you might use an ordinary small photography tripod or lighting stand. The right angle lab clamp can accept any vertical rod.

High-end sportbikes now have lightweight cylindrical plastic reservoirs. You can 3D-print an adapter using something like the brake_fluid-ss9_front.stl (created from brake_fluid-ss9_front.scad) and you can modify this to fit your particular machine.

SpeedBleeders are brake bleeder nipples with spring-loaded one-way check-valve balls. They're a nice idea.

The problem is when you loosen them to release the check-valves, fluid leaks out and air is sucked in past the threads where they screw into the caliper.

You can work around this by smearing grease around the threads or other methods, but it's still a mess.

With Stahlbus bleeders, the nipple with the check-valve screws into an O-ring sealed chamber, which then screws solidly into the caliper. No leaks.

Another advantage of the design is that you can control how loose the valve is, and how easily it passes fluid. You can even loosen them enough to fill the system through the bleeders.